YOUR TRUSTED ADVISORS

Experienced Experts - Custom Solutions

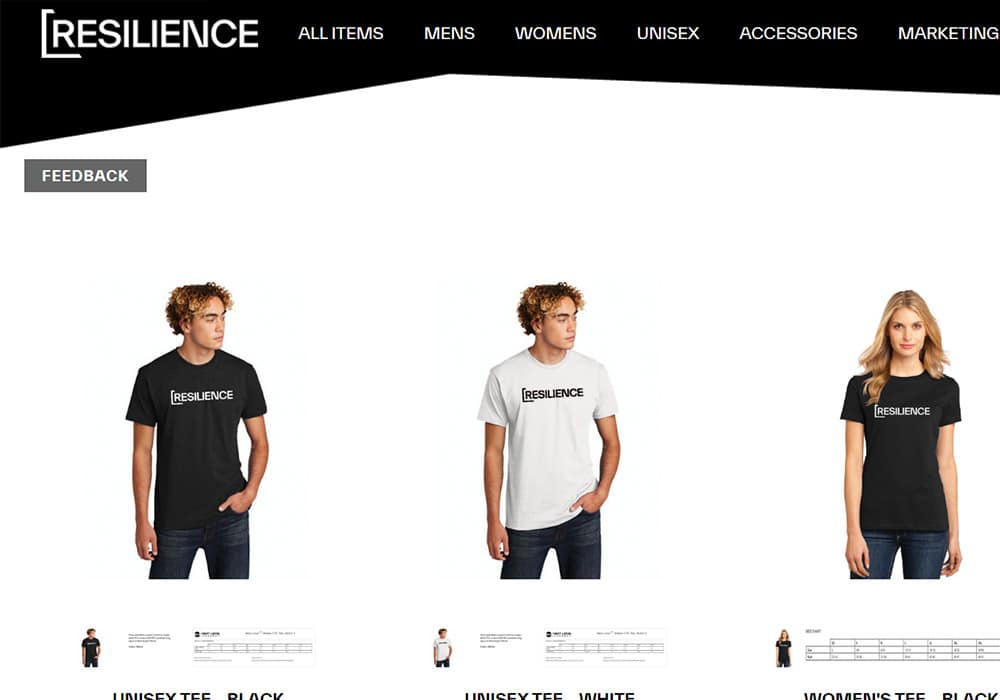

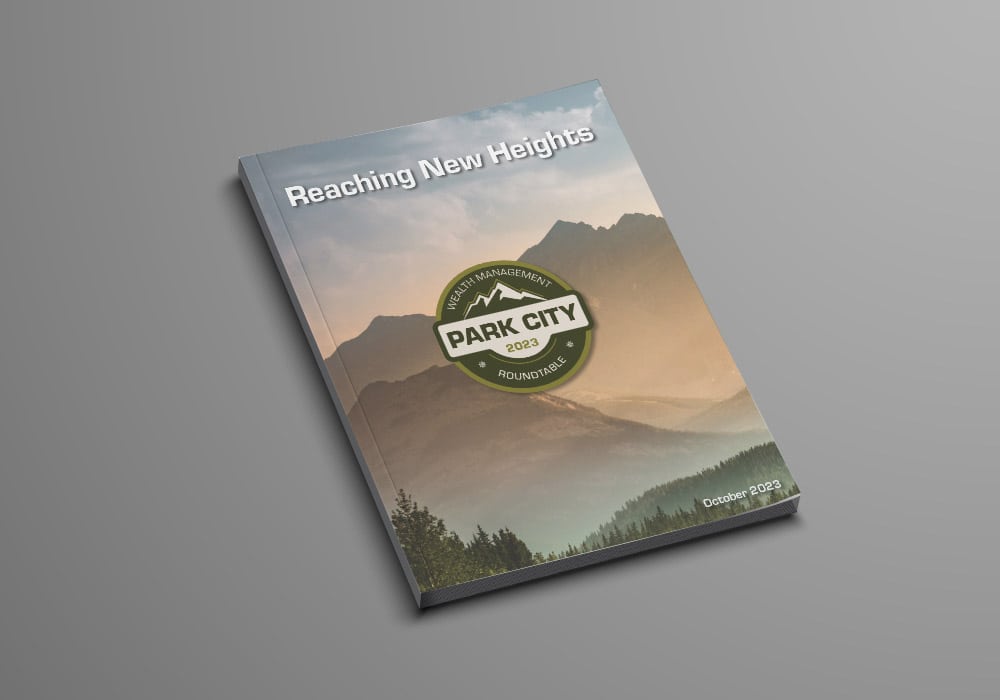

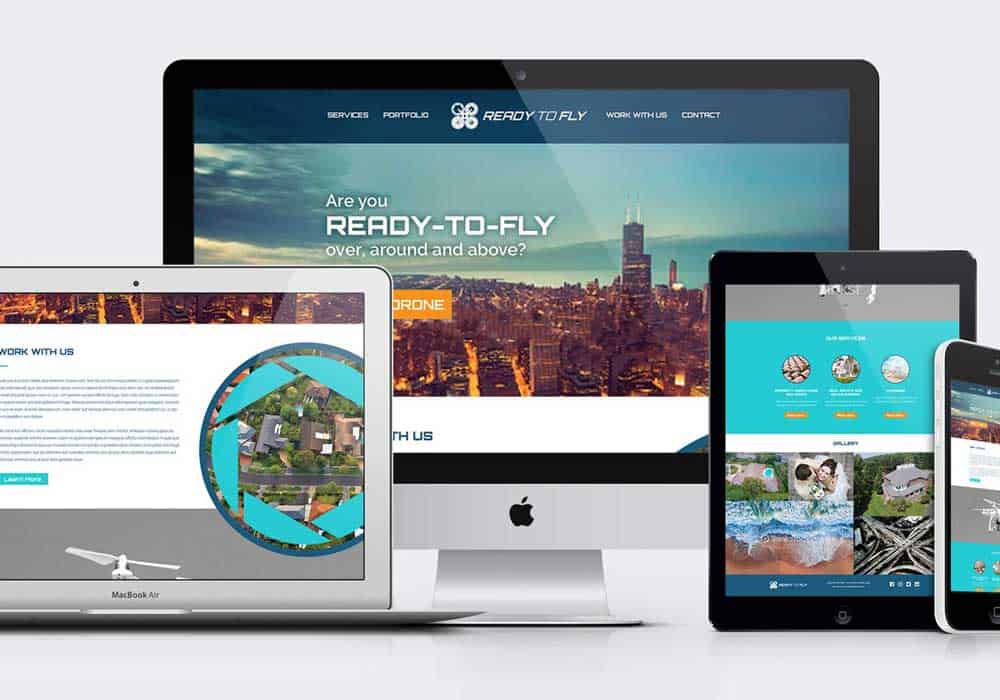

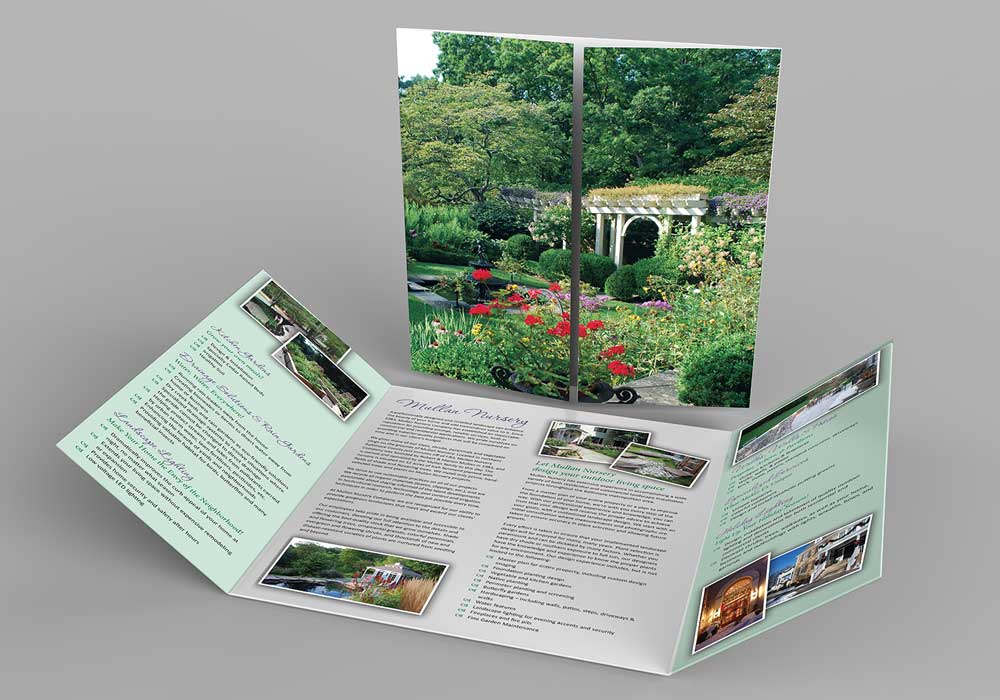

For over 25 years, Strategic Factory has been a family-owned industry leader offering only the best in service and craftsmanship. Headquartered in Maryland with national reach, we’ve grown to expand solutions to include printing and mailing, interior and exterior signage, branded apparel, promotional products, graphic design, marketing strategy, and digital strategy. We’re committed to exceptional customer service as well as growth and innovation, using cutting-edge technology and the latest trends to bring your concept to life.

One Company, Substantial Growth

0

+

Facility Square Footage

0

+

Team Members

0

+

Combined Years of Experience

0

Industries Served

0

+

Customers Served

0

+

Jobs Completed

0

+

Years In Business

News & Events

Strategic Factory invites you to the May ConneX AM networking breakfast powered by Sandler –...

CBS New network features Strategic Factory in its LIVE "Where's Marty?" segment, shedding light on...

Strategic Factory invites you to the May ConneX AM networking breakfast powered by Sandler –...

CBS New network features Strategic Factory in its LIVE "Where's Marty?" segment, shedding light on...

Sip, socialize, and engage in insightful conversations, share industry trends, and network with like-minded professionals....

Let's Make Something Great

For over 25 years, Strategic Factory has been a family-owned industry leader in Maryland, offering only the best in service and craftsmanship in a variety of products and solutions.